des produits

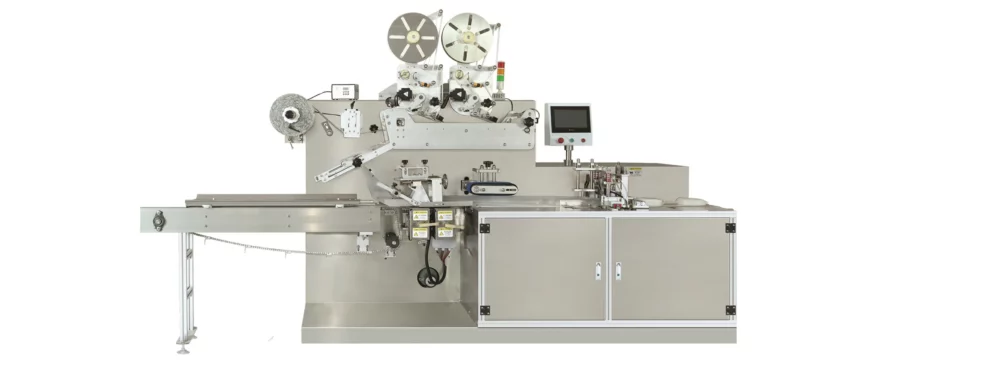

30-120Machine de pliage de lingettes humides pcs 6 voies

Unique benefits of owning our wet wipes machine:

We care what you care most about purchasing a wet wipes machine.

We have always believed in serving best machines possible for customers.

Our mission is to help each client stay at the top of wet wipes supplier.

Description du produit

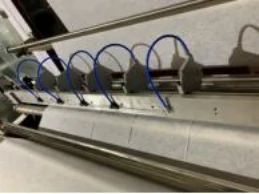

This machine adopts full servo drive and PLC control system for operation. Il est fait d'un dispositif de chargement de matières premières, dispositif de tension, dispositif de pliage, système de mouillage automatique, automatic counting device and stacking device. Stainless steel is applied to the cover of machine and main spare parts. The parts in contact with liquid and fabric are made of stainless steel. All the processes are finished on the machine without manual labor involved, so the finished product meets hygienic standard. The folding device is specially designed to make various folding ways feasible. It’s smart and speedy.

Folding machine system character:

Demander un devis