des produits

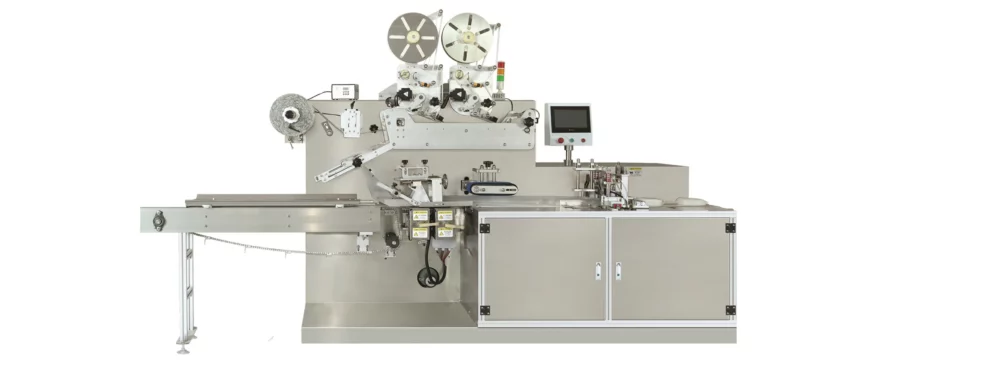

30-120Machine à plier les tissus humides à l'alcool

1.High speed: 3500-4800 pcs/min (25-60bags)

2.Professional manufacturer

3.Top quality

4.High performance

5.Full servo automatic control

6.Easy operation

7.Quality assurance

8.Hygiene products converting solution

9.Customized service

10.Main supported parts from world famous brands.

Description du produit

Paramètre technique principal:

Flux de production:

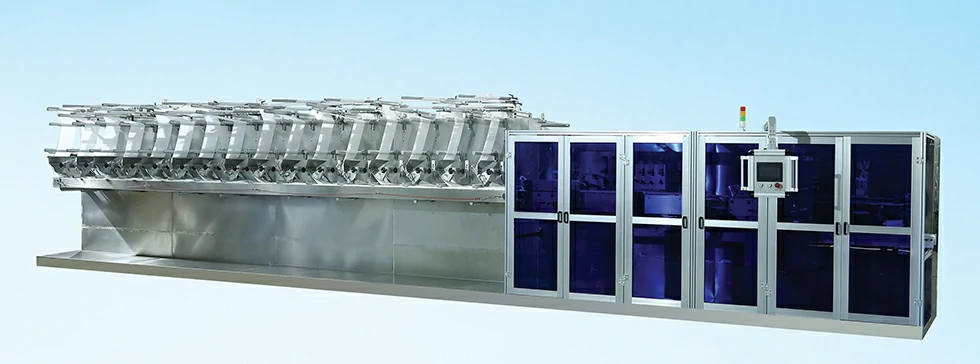

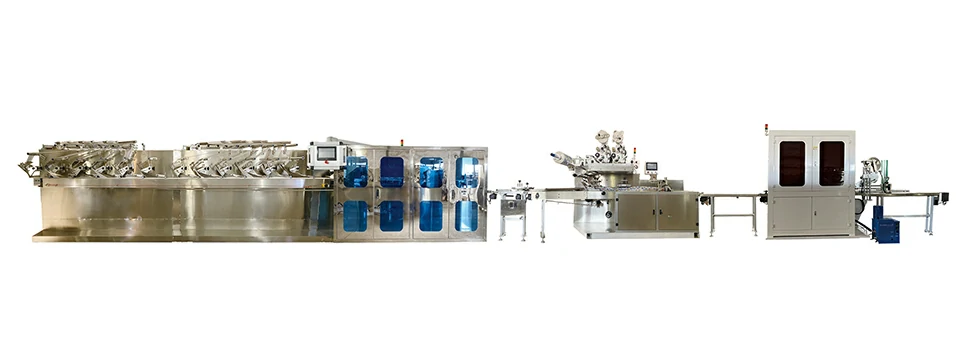

Raw material loading → vertical-folding → tissue wetting → tissue cutting → tissue counting and stacking → tissue delivery → film date Printing, punching and labeling→tissue packing → full auto plastic lid application Product Type: Baby wet wipes; Household wet wipes (30-120pcs/pack)

Technical feature:

This machine adopts full servo drive and PLC control system for operation. Il est fait d'un dispositif de chargement de matières premières, dispositif de tension, dispositif de pliage, système de mouillage automatique, automatic counting device and slitting device, printing and punching device, labeling device, packing and gusseting device, full auto plastic lid application for finished products. Stainless steel is applied to the cover of machine and main spare parts. The parts in contact with liquid and fabric are made of stainless steel. All the processes are finished on the machine without manual labor involved, so the finished product meets hygienic standard. The folding device is specially designed to make various folding ways feasible. It’s smart and speedy.

Demander un devis