products

Product description

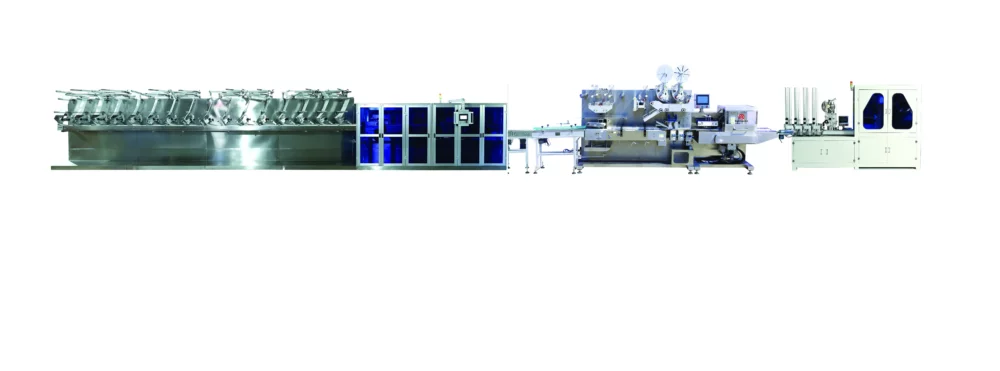

This machine is designed as automatic production solution for sanitary wet wipes and Make-up removing wet wipe and personal care wet wipe. It can be adjustable for fit to various packaging sizes, a perfect choice for OEM and ODM factory who produce different sizes of wet wipe products on one machine.

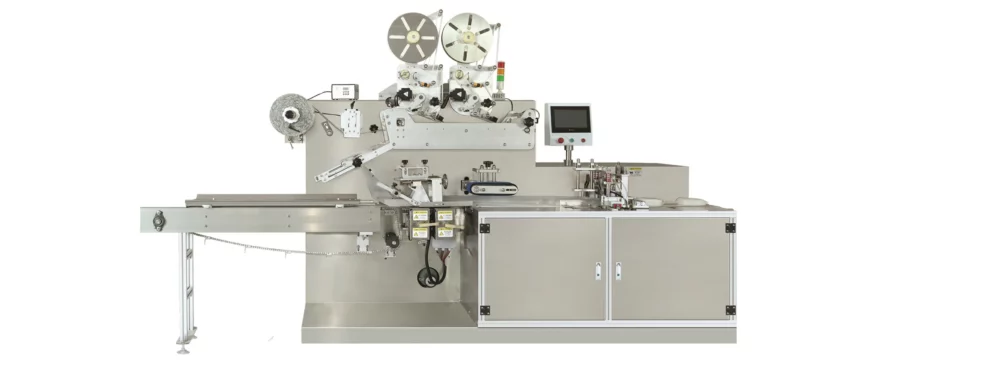

This machine with the advanced technology, servo motor and PLC touch panel, which can adjust the packing temperature, packing speed and tissue length accordingly. This machine adopts light electrical integration design, with the function of automatic error alarm system and safety instruction signals. With stable performance, simple operation, the continuous air pressure ensures the good sealing of products.

Product introduction

Loading one packing film roll → 1st sealing (left+right+bottom sides) → loading two non woven rolls → folding → cutting off → inserting tissue & filling liquid → 2nd sealing (left+right+up+bottom sides) → embossing Lot No.→ tear/notch making → cutting off & output by robot arm.

Main Technical Parameter:

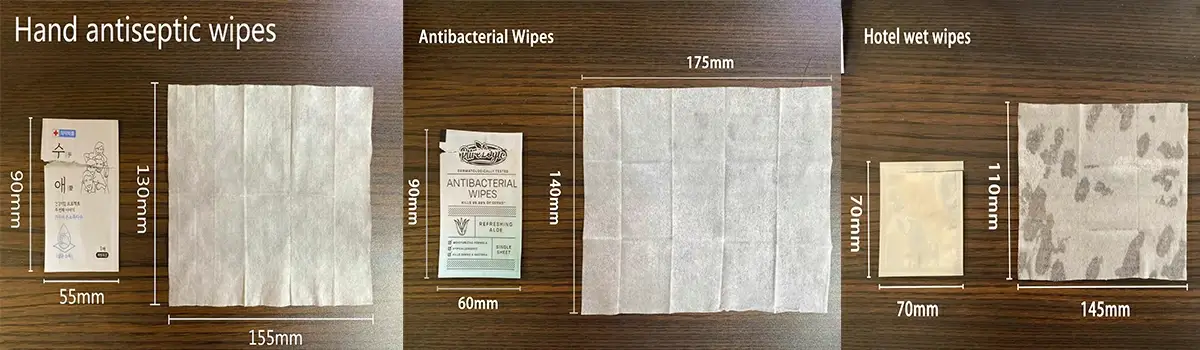

Application

This machine is suitable for the production of all kinds of four-side sealing wipes, make-up removal wipes, personal care wipes, alcohol pads, etc. One machine can produce a variety of different package sizes products(wet wipes).

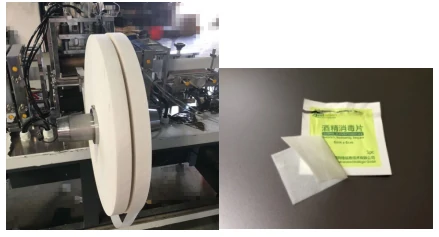

Samples

Structure

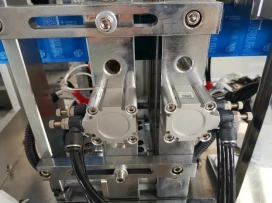

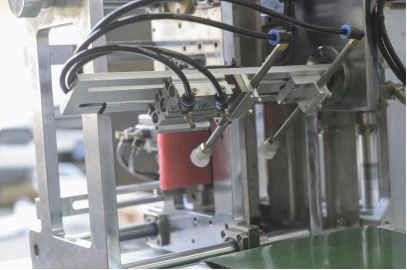

Part name:Liquid pump

This part is more accurate to add liquid into different packages with tolerance of ±0.01ml/time

Part Name: Adjustable mold + ruler

The machine has the design of adjustable mold which can produce different sizes of wet wipes.

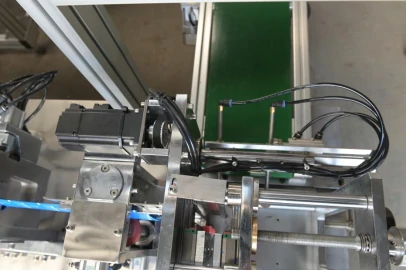

Parts name: Servo motor + Air cylinder

The machine is compact in structure, the drive system only uses servo motor and air cylinder. To ensure the oil-free operation, there is no need of replacing the spring or adding lubricating oil in the machine. It makes the machine keep clean, no matter how long it works, the products are always in high quality.

There are 5 servo motors, which are used to control the mechanical movement of non-woven drive, packaging film drive, non-woven cutting, non-woven filling and packaging bag taking out. And the 10 air cylinders to control the sealing, cutting, data printing and so on. Compared with ordinary wheeled machinery, it guarantees reliable performance, accuracy, low energy consumption, low maintenance cost and other advantages. There is an experienced technical team to run and maintain the machine, and the machine has few easily damaged parts, thus saving the customers’ after sales cost.

Part name: Tissue folding device

The folding range is wide.Max 10 times folding vertical, and 4 times folding horizontal

Part name:Alcohol pad rolling shelf

This part is optional ,it’s suitable for producing alcohol pad 60mm x 30mm

Part name: Robot arms

Controlled by servo motor and cylinder to ensure stable and clean operation, finished bags can be set up in piles freely, making the packing process more convenient.

Date Printing and Punching:

It can punch two kinds of type, the “V” type or the “-”type.

Steel letters and numbers printing for date and batch code

Packing and Delivery:

Request A Quote